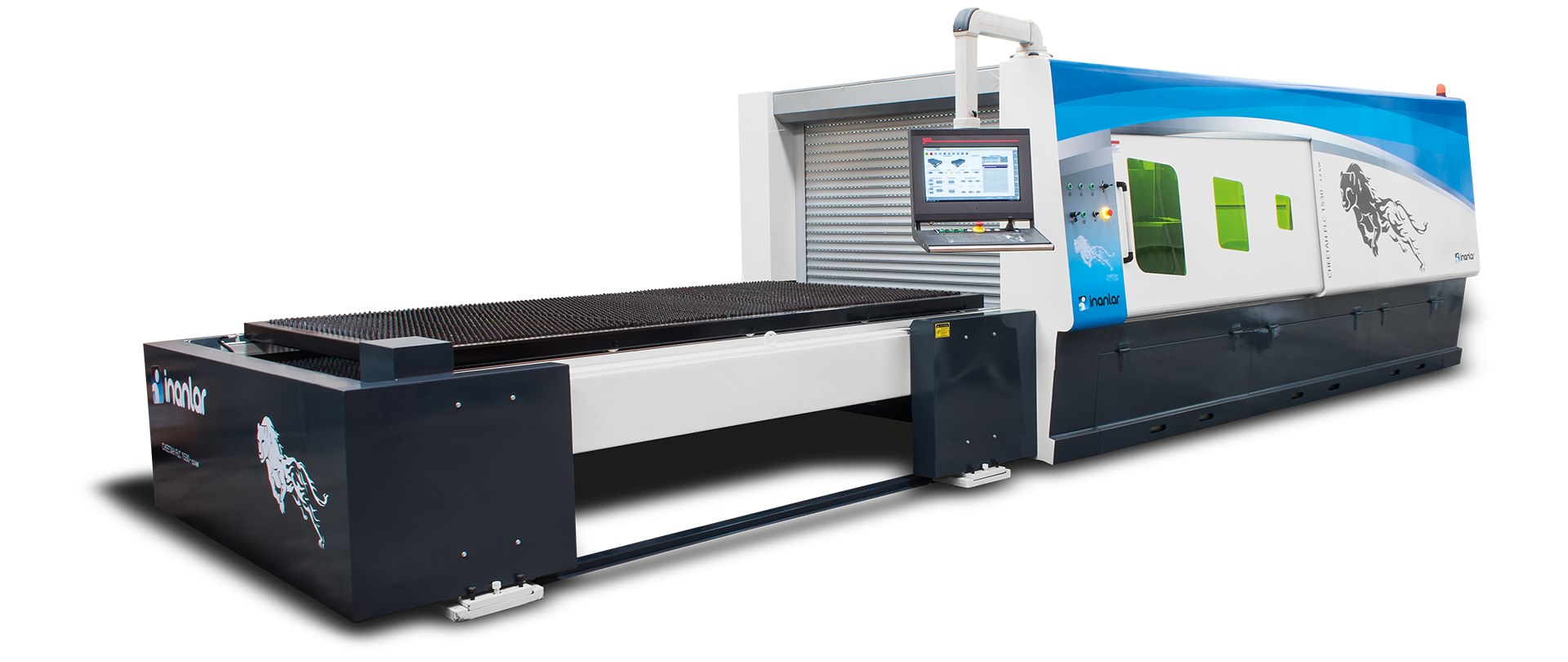

Cheetah - Fiber Laser Cutting Machine - More details> -Economic -Accuracy -Fast

CNC Fiber Laser Cutting Machine

Fiber Laser cutting technology is less then CO2 laser cutting machines requiring maintenance , fast and high energy efficiency. We aimed to provide our customers with high afficiency ,precise and easy-to-maintain products with precise cutting edge technology and reducer selection that we use in our machine.

ADVANTAGES

- High efficiency

- Low energy requirement

- High cutting ability in all kinds of materials

- Low material consumption

- Low maintenance requirement

- High speed cutting

- High Beam quality

- Modular design

- Increase production with FlyCut and FastCut technology.

- nLight alta Fiber Laser source

- LaserMech Cutting head

- Chiller

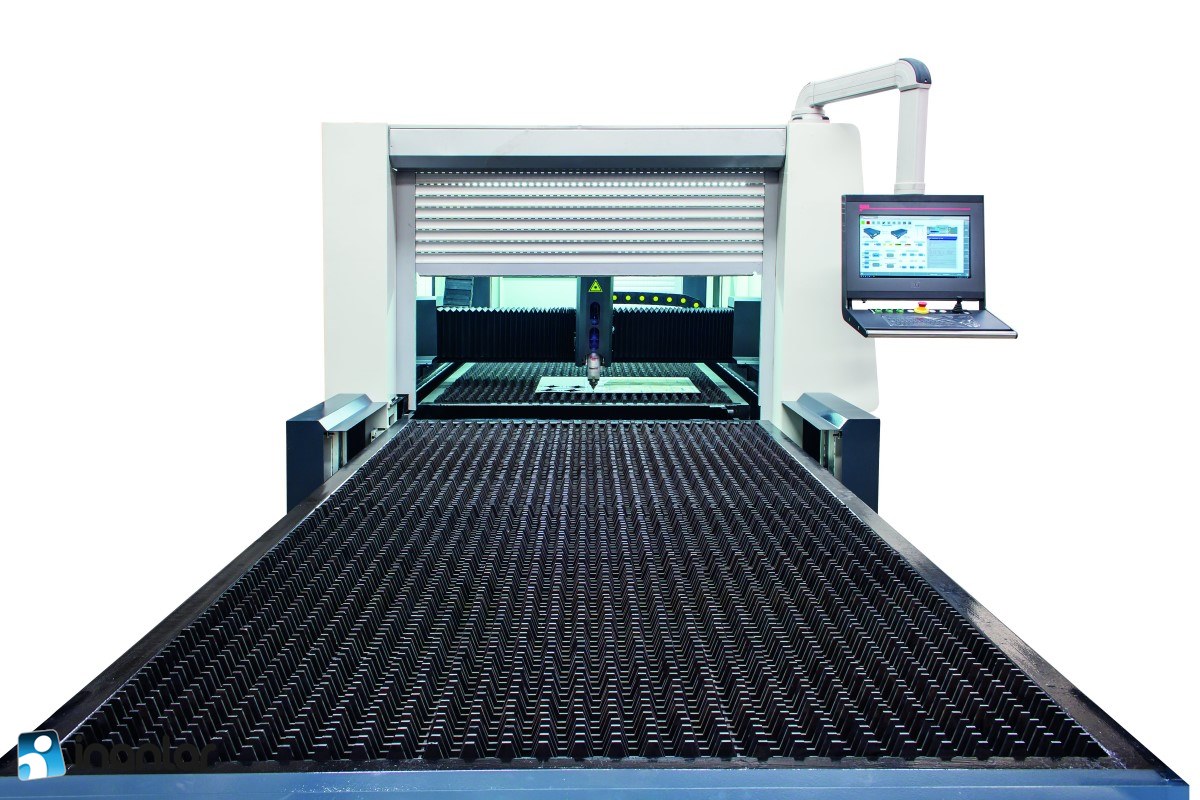

- 21" Multitouch ESA CNC Control Unit

- Servo drive movement system

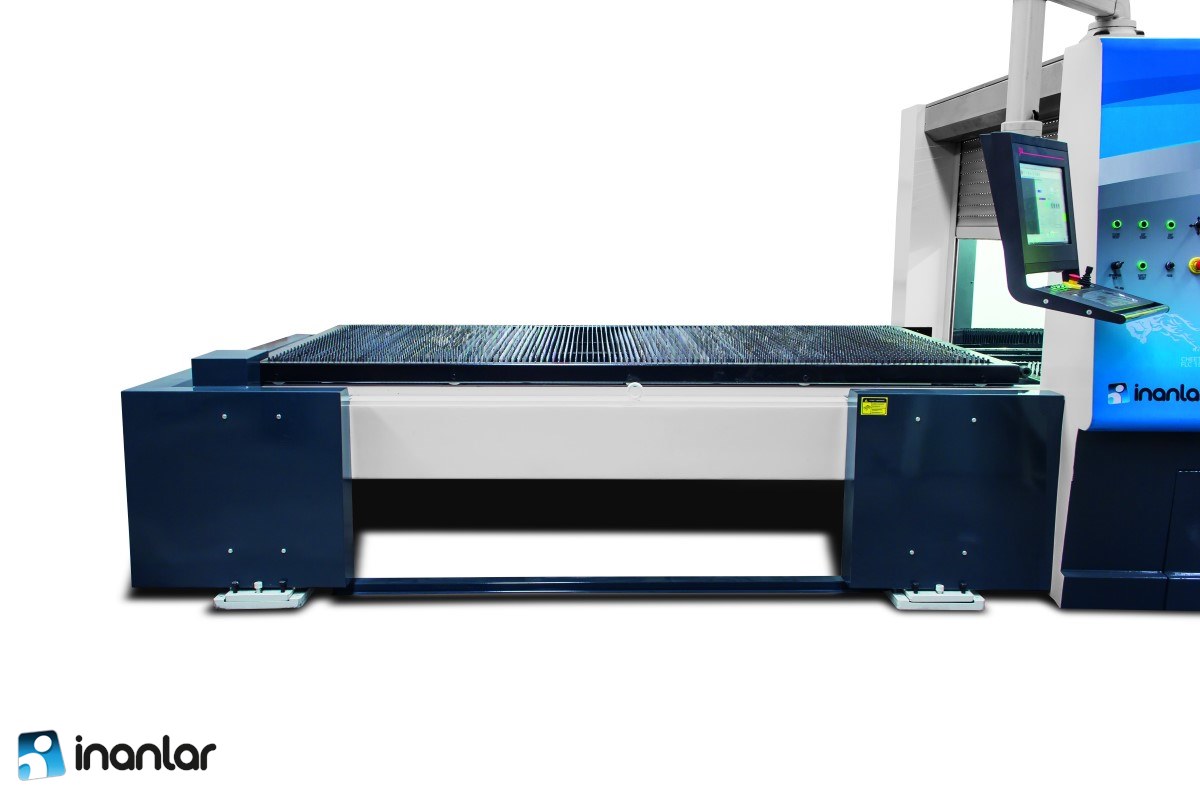

- Single table

- Drawer system

- Light body guard for shuttle table

- Automatic Nesting software

- Smoke extraction system

nLIGHT ALTA ™ is the first product in a new generation of high power fiber lasers to meet the rapidly changing needs of processing industrial materials. nLIGHT ALTA ™ fiber lasers are manufactured with leading laser diodes and fiber technologies, and have the first safe rear reflector isolation technology for full processing of highly reflective materials.

- CAD/CAM system allows to configure and manage the type and value of lead-in/lead outs for different types of contours.

- Common line cutting can be achieved on several parts or just limit to pairs of parts. With microjoints and pre-cuts.

- It detects errors in the design and machining.

- CAD/CAM system has automatic lead-ins, manual and automatic cutting, machining copy, customised machine configuration and postprocessor for all types of machine.

- CAD/CAM system are fully integrated in a single program, so designing a part, importing, nesting (automatic or manual), generating the cut (automatic or manual), generating the CNC, looking at the sheet metal store, etc. will be achieved from the same program without switching between programs.

- CAD/CAM system is ready for connection to production management systems (ERP) by means of automatic processes.

- Teamwork. Available for operation as a stand alone productivity cell, or as part of a network system.

- Parts management and sheet store with open databases. All parts info is saved in databases organised in such a way that users can easily locate the part and sheet required, as these are classified by fields like material, thickness, date, customer, etc. The remnant automatically generated by the system is saved in the sheet inventory like any other sheet metal and can be used for future jobs.

- Large library of parametric parts.

- Calculation of real time and cost. CAD/CAM system calculates time and cost of cutting any part and also the entire sheet. Taking into account the number

- of piercings, the cut length, the mark length, the material costs, the hourly machine rate, the cost of consumables and based on the technological machine data.

- 2D design. CAD/CAM system includes advanced options for geometry and edition.

- Smart Importer/Exporter. Connection with the most important CAD systems on the market: DXF, DWG, IGES, etc.

• User friendly and easy interface

• Easy access to cutting parameters

• Fast data processing with 64-bit operating system

• Multitouch screen

• 2 pcs. USB port

• Keyboard system supported by touching physical buttons.

• Simulation mode.

• Ability to change cutting parameters at cutting operation

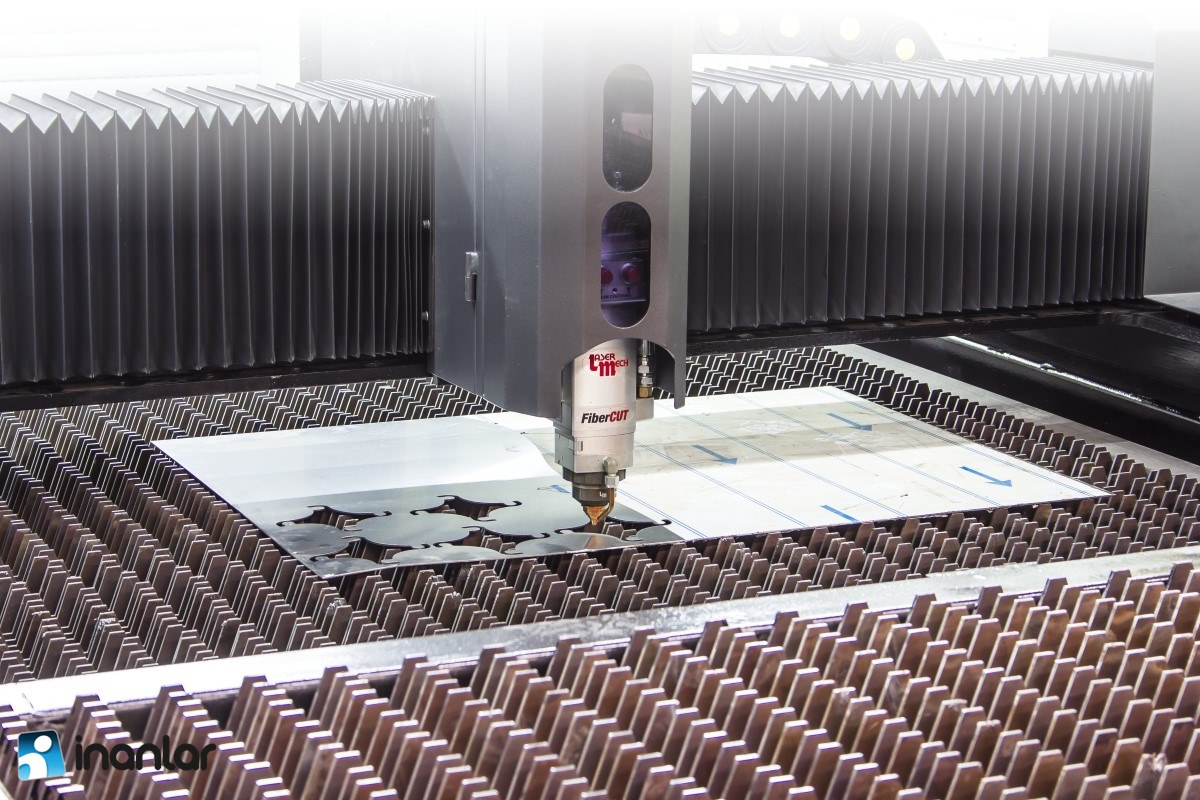

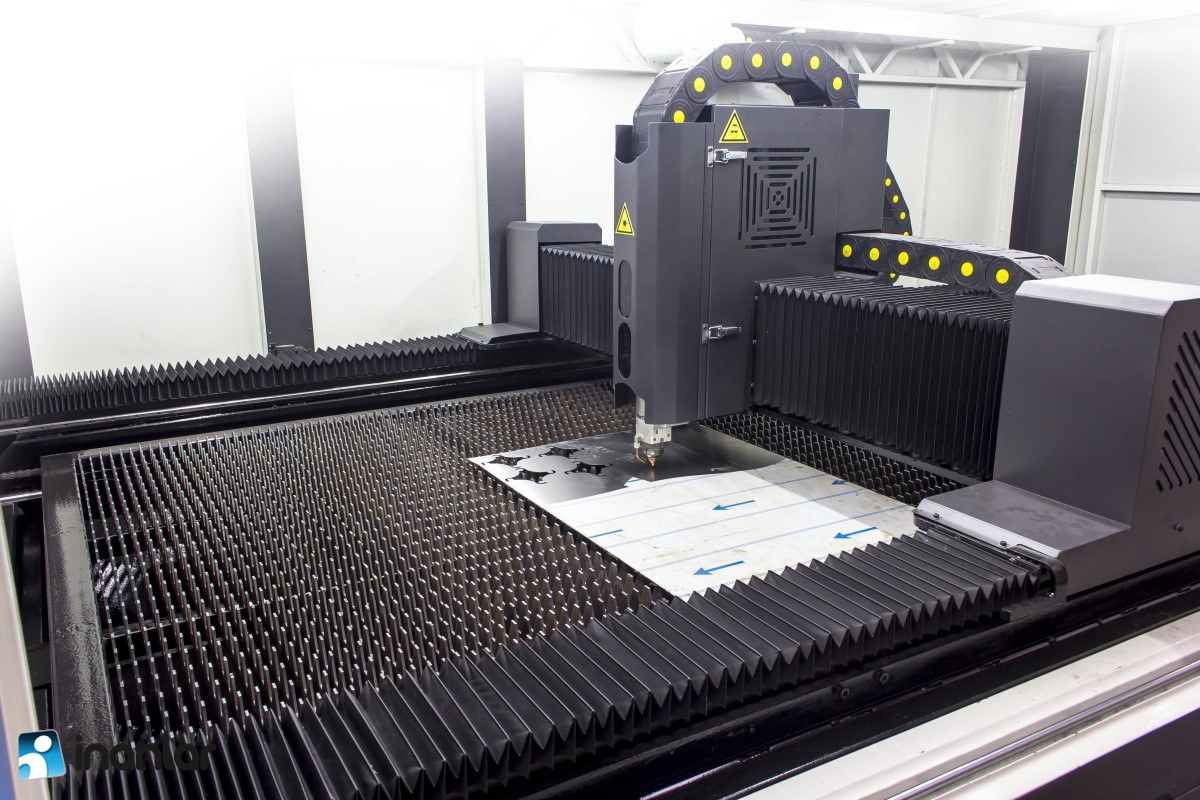

Laser Mechanisms’ FiberCUT® 2D processing head delivers cutting-edge performance for flatbed systems up to 6 kW. Featuring automatic, programmable focus with 25 mm of travel, FiberCUT® 2D is a fully-sealed, purged design that minimizes the chance of internal contamination. FiberCUT® 2D goes even further with two cover glasses; one below the focus lens, and a second below the fiber to protect collimator optics. In addition, sealed access doors prevent contamination when cover glasses are serviced.

- Internal process monitoring to detect pierce through and loss of cut

- Internal sensors to determine the condition of all optics

- Standard nozzle cooling and air blast

- Lightweight (6,6 kg)

- Laser Mech®’s patented height sense technology

- Auto Focus

- Auto calibrating height sensor

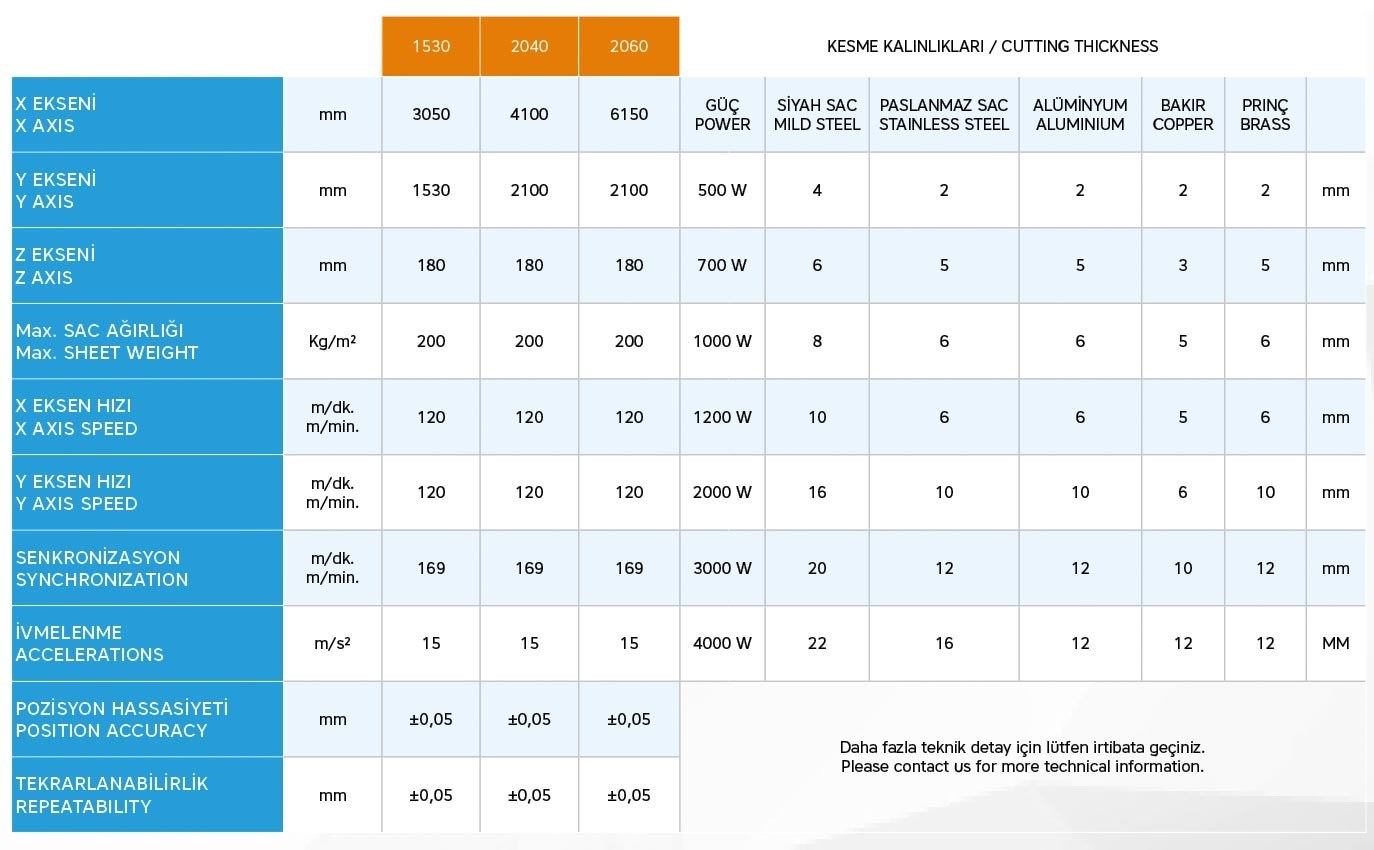

The machine axis movements are transferred of servo motor , rack and pinion , Microbacklas (1arc/min.) reducer and pinion ,position tolerance (0.05 mm) with high speed (120 m/min) and high acceleration (15m/s²) .

- High efficiency

- Low energy requirement

- High cutting ability in all kinds of materials

- Low material consumption

- Low maintenance requirement

- High speed cutting

- High Beam quality

- Modular design

- Increase production with Flycut and Fast Cut.