ModEva Pac and Cybtouch 12 is a natural evolution of Cybelec's famous numerical controls.Its the latest evolution of the Cybelec's user interface empowers the operator to interact in a quick,convenient and more efficient manner with his machine, ultimately increasing his productivity.

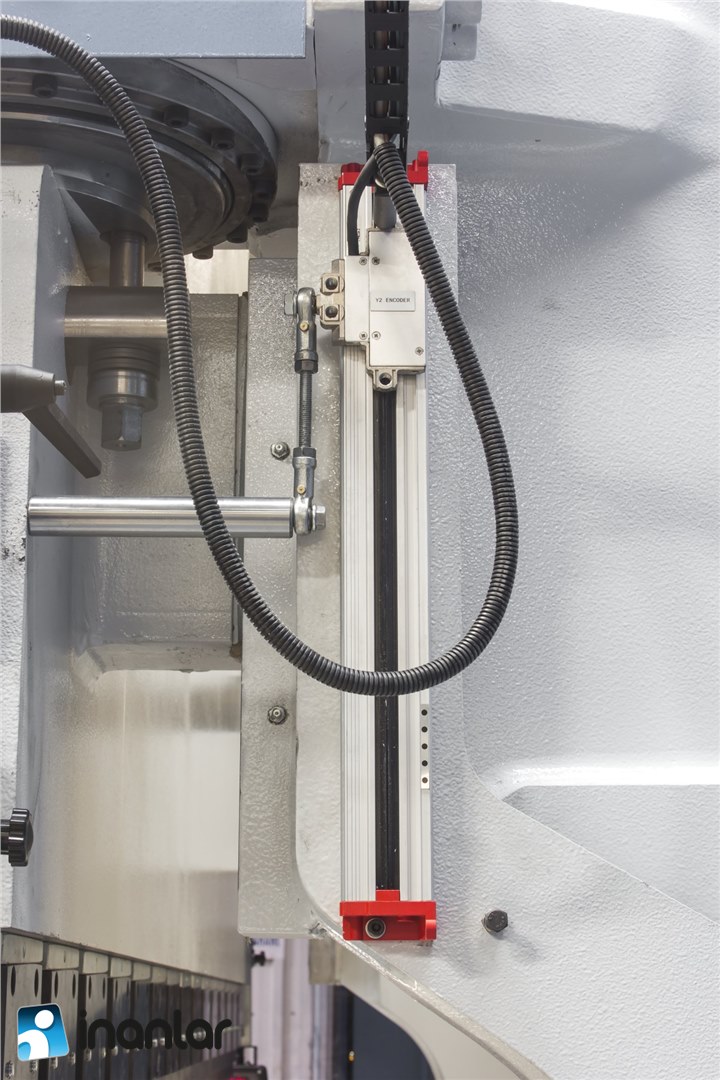

-4 axes control (Y1-Y2-X-R).

-TouchProfile 2D graphic part creation with manual sequencing.

-Bend allowance calculation.

-Pressure – crowning calculation.

-Modulable tools for each part or bend.

-Punch depth calculation.

-Angle and back gauge correction.

-Delivered with PC-ModEva offline software.

-Large touchscreen, with vivid colors and high-contrast.

-Hand drawing TouchProfile function.

-Simple pages, clear display, large keys.

-Intuitive and user-friendly interface.

-Complete programming for efficient mass-production with multiple bends.

-Easy single bends thanks to the EasyBend page.

-Online help and interactive warning pop-up.

-Comfortable wireless software updating and data back-up using PC or Notebook.